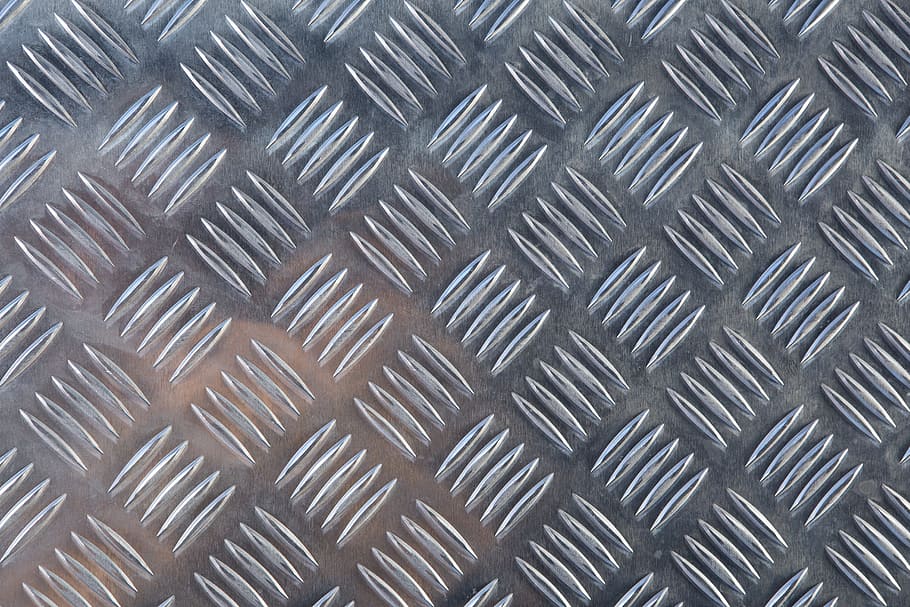

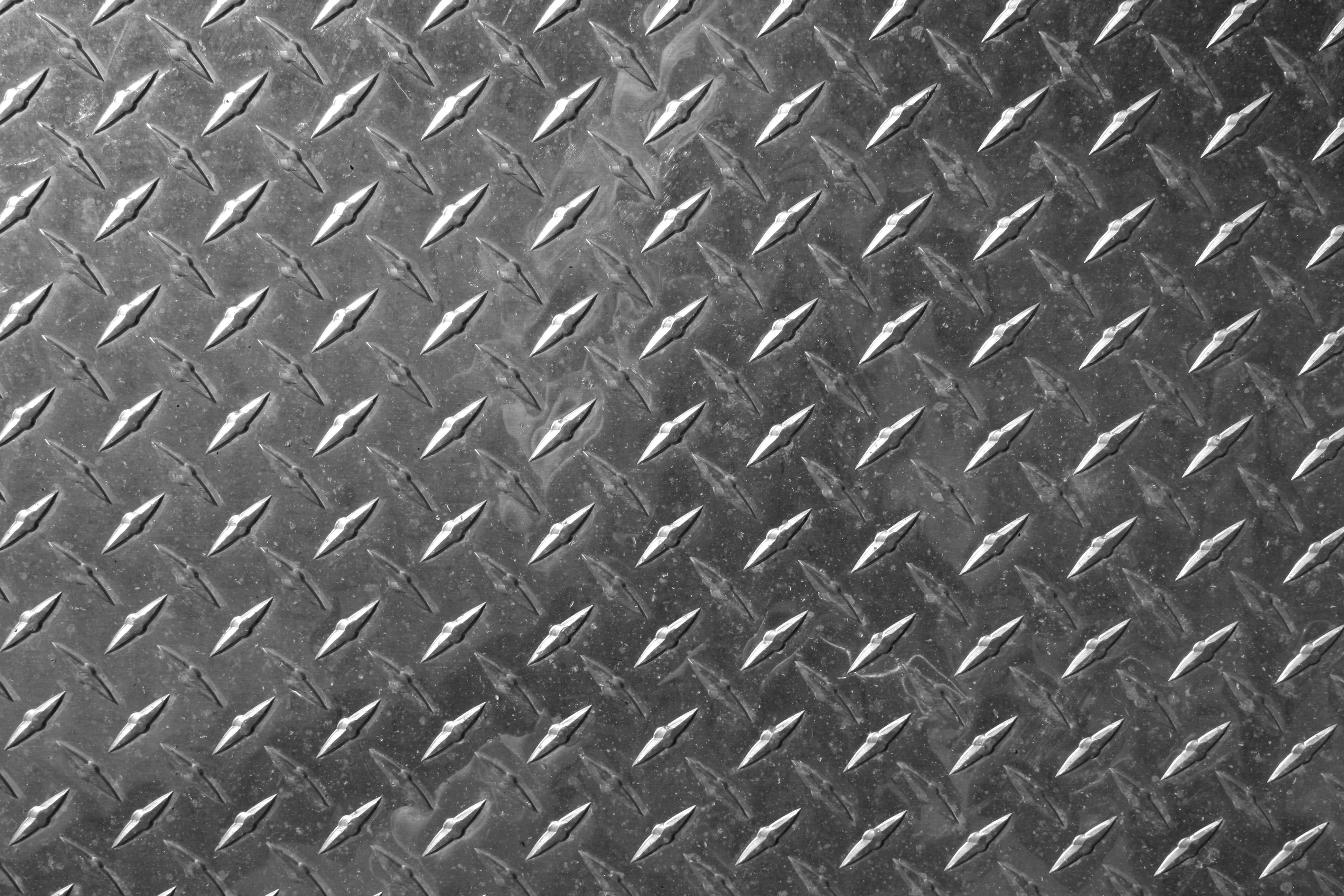

Topics covered included creating features in the sheet metal flat pattern, exporting to dxf/dwg, and more. Sheet metal flat patterns are done in plane geometry. Sheet metal stamping is a great way to make a. Metal thickness is.030″ or.063″ other thicknesses are. Square, triangle, hexagon, etc.) and circles on a flat surface (plane).

Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Web check out our sheet metal patterns selection for the very best in unique or custom, handmade pieces from our kits & how to shops. Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Web check out our metal sheet patterns selection for the very best in unique or custom, handmade pieces from our tutorials shops. Triangulation is a practical approach to pattern development.developing patterns is an essential part of sheet metal work.

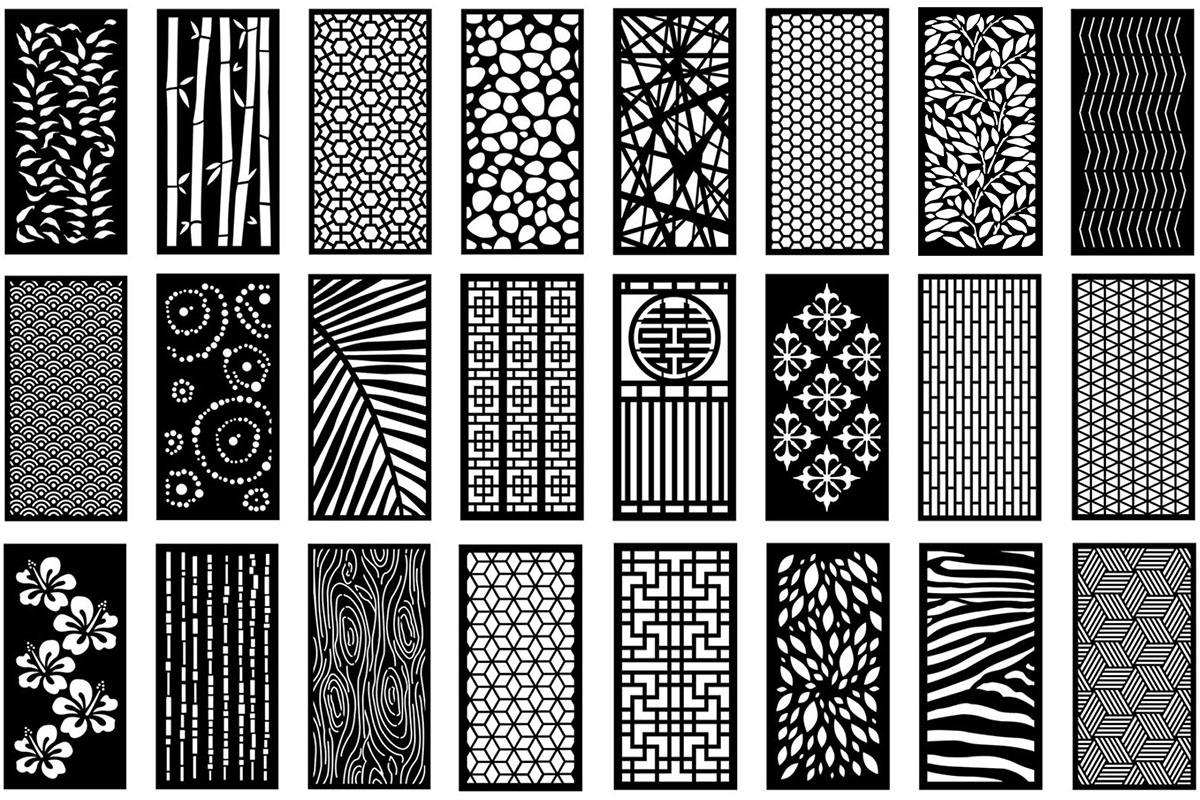

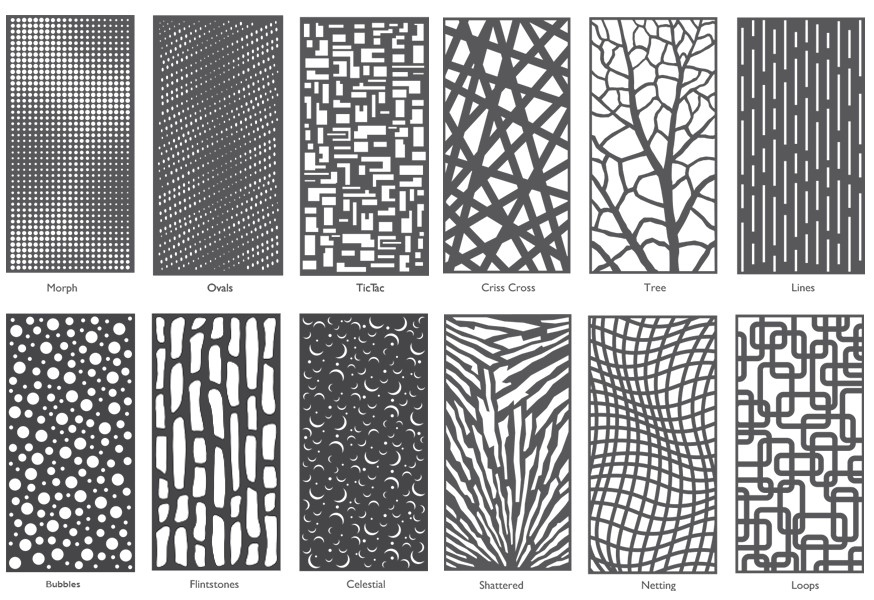

Web sheet metal forming makes use of a number of processes to transform a flat sheet of metal into metal parts that are durable and lightweight. Web practical sheet metal work and demonstrated patterns. Web sheet metal is easy to cut, bend, and form. Layout for square to round. Browse our metal wall panel designs and choose your favorite, or design your own wall covering.

Web check out our pattern sheet metal selection for the very best in unique or custom, handmade pieces from our metal shops. Web we have the widest selection of wall panel patterns on the market. Material available in stainless steel or aluminum other metals available on request. Standard sheet size available is 48″x 96″. Web check out our metal sheet patterns selection for the very best in unique or custom, handmade pieces from our tutorials shops. Web this book covers all three forms of layout as well as geometric construction. Normally large sections of sheets are applied. Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal flat patterns are done in plane geometry. Triangulation is a practical approach to pattern development.developing patterns is an essential part of sheet metal work. 3d cad files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part. Jaigyan language english item size 3210330520. Bending, shearing, punching, and hydroforming are all examples of processes that are used to form or cut metal sheets into the desired shape. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Sheet metal stamping is a great way to make a.

Extremely Thin Sheets Are Considered Foil Or Leaf , And Pieces Thicker Than 6 Mm (0.25 In) Are Considered Plate, Such As Plate Steel, A Class Of Structural Steel.

It introduces the learner to the techniques used in parallel line, radial line, and triangulation. Web practical sheet metal work and demonstrated patterns. This is an introduction to the. Solid geometry deals with points, lines, and planes in space, (3 dimensional).

Web Sheet Metal Pattern Layouts By Anderson Edwin P.

Normally large sections of sheets are applied. Web this book covers all three forms of layout as well as geometric construction. Web plane geometry deals with points, lines, polygons (a shape with more than two sides, i.e. 14 videos 669 views last updated on sep 29, 2019.

3D Cad Files Are Converted Into Machine Code, Which Controls A Machine To Precisely Cut And Form The Sheets Into The Final Part.

Layout for square to round. Web sheet metal forming makes use of a number of processes to transform a flat sheet of metal into metal parts that are durable and lightweight. Bending, shearing, punching, and hydroforming are all examples of processes that are used to form or cut metal sheets into the desired shape. Web check out our pattern sheet metal selection for the very best in unique or custom, handmade pieces from our metal shops.

Sheet Metal Fabrication Is The Process Of Forming Parts From A Metal Sheet By Punching, Cutting, Stamping, And Bending.

Web accurate perforating offers a perforated pattern for everyone, from basic stock perforations to complex patterns, whether you need it to suit a decorative or functional requirement. Triangulation is a practical approach to pattern development.developing patterns is an essential part of sheet metal work. Sheet metal stamping is a great way to make a. Choose from our standard round staggered, round straight, slot, square, decorative patterns, and much more.