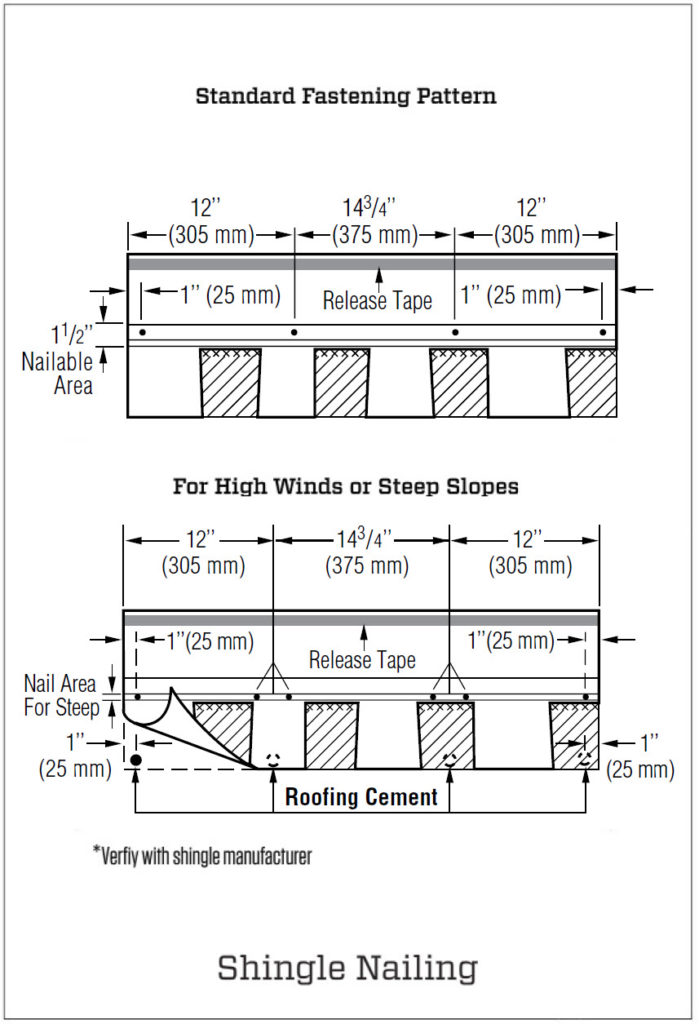

The purpose of this sample board is to show the proper nail position for three tab shingles. Measure the layout and purchase shingles. Nail each shingle with four nails, positioning them just below the adhesive strip and near the edge. The metal a nail is made from can make all the difference not only in how well it holds down a shingle, but also how long it lasts over time. Updated sep 15, 2021 reviewed by.

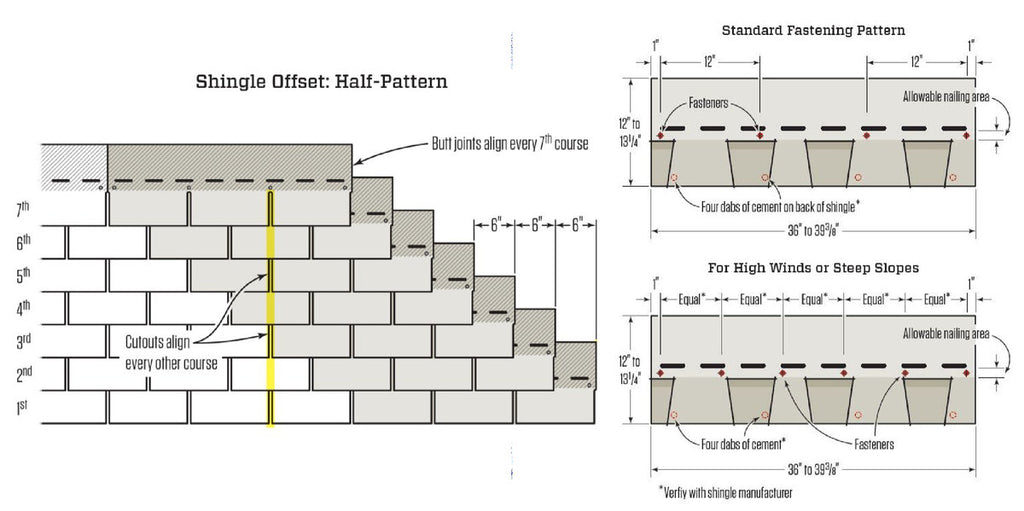

Architectural shingles, being thicker and heavier, require a bit more fastening. Place nails at the designated spacing specified by the shingle manufacturer, typically around 6 to 8 inches apart horizontally and 1 to 2 inches from the edges of the shingle. Of the underlying shingle (as a secondary fastener). This ensures they stay in place and don’t risk being exposed, which can cause corrosion and leaks. Web most shingles require either a 4 or 6 nail pattern per shingle to ensure a tight seal.

Web when embarking on a roofing project, selecting the right type of nails is crucial. Learn about selecting the correct type of shingles, nailing techniques, overlapping and aligning rows, and completing the installation with finesse. Look out for underdriven, overdriven, or angled nails during installation to reduce the risk of installation issues. This chapter will demonstrate how to properly nail roofing shingles. This ensures they stay in place and don’t risk being exposed, which can cause corrosion and leaks.

Web how many nails per shingle? Web keep in mind that the nails should hit both the shingle being installed (as a primary fastener) and also the top 1 in. Web most shingles require either a 4 or 6 nail pattern per shingle to ensure a tight seal. Web one of the key components to shingle performance, regardless of manufacturer, is proper nailing. Can i use staples for roofing? When installing thicker shingles, you may need to use a longer nail in order to penetrate the osb beneath fully. Measure the layout and purchase shingles. Web nail the shingles in place using a roofing nail gun or hammer, driving nails into the designated nailing areas on the shingles. Web nailing pattern for architectural shingles. Coil roofing nails for nail guns. This ensures they stay in place and don’t risk being exposed, which can cause corrosion and leaks. Web when embarking on a roofing project, selecting the right type of nails is crucial. Nail each shingle with four nails, positioning them just below the adhesive strip and near the edge. Web building materials & supplies. This guide provides an extensive overview of roofing nails for shingles, ensuring you.

Typically, Use Four Nails Per Shingle, Placing Them About 1 Inch Above The Cutouts And 6 Inches From The Ends.

Roofing nails are specifically designed for attaching shingles to roof decks, and choosing the correct type can significantly impact the durability and longevity of your roof. Web strike nails at a 90 degree angle from the roof when hammering by hand. Use a consistent nailing pattern across the roofing material to ensure uniformity and structural integrity. Always adjust nail guns appropriately to avoid improper fastener installation.

These Shingles Are For Application To Roof Decks Consisting Of Plywood, Oriented Strand Board (Osb) Or Sheathing Boards Capable Of Receiving And Retaining Fasteners, And To Inclines Of Not Less Than 2 Per Foot.

How many nails per roofing square? Nail each shingle with four nails, positioning them just below the adhesive strip and near the edge. Place nails at the designated spacing specified by the shingle manufacturer, typically around 6 to 8 inches apart horizontally and 1 to 2 inches from the edges of the shingle. Look out for underdriven, overdriven, or angled nails during installation to reduce the risk of installation issues.

Web Most Shingles Require Either A 4 Or 6 Nail Pattern Per Shingle To Ensure A Tight Seal.

Refer to the gaf pro field guide for additional tips. Of the underlying shingle (as a secondary fastener). When installing thicker shingles, you may need to use a longer nail in order to penetrate the osb beneath fully. Web a large nailing area can make shingles easier and quicker to install while also increasing nail placement accuracy to help secure them better to the roof structure.

Coil Roofing Nails For Nail Guns.

The metal a nail is made from can make all the difference not only in how well it holds down a shingle, but also how long it lasts over time. Web nail the shingles in place using a roofing nail gun or hammer, driving nails into the designated nailing areas on the shingles. Web here’s the best way to install roof shingles, where to nail shingles, how much to overhang the drip edge, and fit the felt paper. That's why gaf's timberline ® shingles with layerlock™ technology * were designed with the strikezone™ nailing area, the industry's largest nail zone.