Web in this video, i show you how i create a pattern for a particular knife. 1) draw out the pattern 2) check the knife against the pattern 3) cut the leather to match the pattern 4) check the knife's positioning against the leather cut out 5) cut the welt from the pattern 6) compare welt pattern position to knife fit 7) us barge cement to glue the welt 8) hammering down the welt 9) punching holes for snap. Web design and build your own knife sheath. We do have a video showing how we make a completed sheath. Web check out our knife sheath patterns selection for the very best in unique or custom, handmade pieces from our hunting & archery shops.

Butt, beginning, middle, and end of a handle, bolster/guard, and a blade in 3 or 4 places). My pattern uses the tooling window to size the finished sheath to fit a particular knife. I build a lot of stuff in the past, but this was the first time i made anything from leather. Web the “ss” stamping of randall forged blades began in 1963, when rmk started designating stainless blades as such. Lay the knife out on your piece of cardboard and roughly trace around the blade and as much of the handle as you want to cover with your sheath.

It’s a simple design meant to protect the blade and sit close and comfortably on the hip. Butt, beginning, middle, and end of a handle, bolster/guard, and a blade in 3 or 4 places). We do have a video showing how we make a completed sheath. Check out the video above to see how i made the sheath. By using this kit, you will learn indian techniques, including how to paint parfleche by.

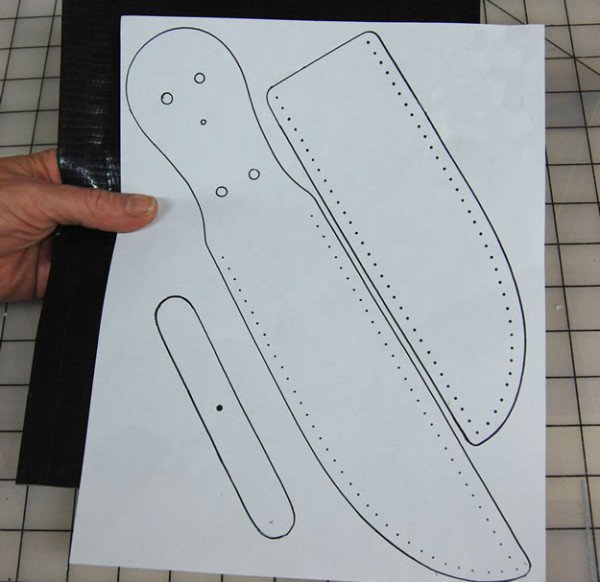

Web in this tutorial i am going to guide you through all of the steps needed to create this leather knife sheath. Web i have developed a set of patterns to use when making these that will cut out all the fitting issues for most knives. They hold themselves to high standards of quality, design, and performance. Web for a complete list of products used in this video series visit: It should match the function and appearance of the knife. This style of knife sheath is called a pancake knife sheath. We give you tips on how to develop your knife sheath from scratch and what you should bear. Web if you need pattern for a knife sheath start from drawing shape of your knife on a piece of paper. 1) draw out the pattern 2) check the knife against the pattern 3) cut the leather to match the pattern 4) check the knife's positioning against the leather cut out 5) cut the welt from the pattern 6) compare welt pattern position to knife fit 7) us barge cement to glue the welt 8) hammering down the welt 9) punching holes for snap. A seemingly simple project has me stumped, does anyone have couple of different style patterns you could share? My pattern uses the tooling window to size the finished sheath to fit a particular knife. Web in this video, i show you how i create a pattern for a particular knife. We do have a video showing how we make a completed sheath. Web the “ss” stamping of randall forged blades began in 1963, when rmk started designating stainless blades as such. Web for homemade knife sheaths, there are two basic types you can make:

Web Drawing On Over 10 Years Of Custom Sheath Making Experience, Diomedes Industries Can Make You A Truly Custom Sheath For Your Blade.

Web check out our knife sheath patterns selection for the very best in unique or custom, handmade pieces from our hunting & archery shops. Web if you need pattern for a knife sheath start from drawing shape of your knife on a piece of paper. 1) draw out the pattern 2) check the knife against the pattern 3) cut the leather to match the pattern 4) check the knife's positioning against the leather cut out 5) cut the welt from the pattern 6) compare welt pattern position to knife fit 7) us barge cement to glue the welt 8) hammering down the welt 9) punching holes for snap. My pattern uses the tooling window to size the finished sheath to fit a particular knife.

Our Books And Waitlist For Custom Sheaths Are Currently Full.

Web design and build your own knife sheath. They are all forged in fire champions. Web how to make a leather sheath. Web for a complete list of products used in this video series visit:

Web The “Ss” Stamping Of Randall Forged Blades Began In 1963, When Rmk Started Designating Stainless Blades As Such.

It should match the function and appearance of the knife. This style of knife sheath is called a pancake knife sheath. It may have run into 1964, but it was not done this way much beyond a six month duration, and that may even be generous. It’s a simple design meant to protect the blade and sit close and comfortably on the hip.

Check Out The Video Above To See How I Made The Sheath.

Web i have developed a set of patterns to use when making these that will cut out all the fitting issues for most knives. We do have a video showing how we make a completed sheath. Web in this tutorial i am going to guide you through all of the steps needed to create this leather knife sheath. Web custom sheaths are specifically customized to your exact knife, therefore all customs sheaths require the knife to be sent to the shop in order for the sheath to be created.